MANUFACTURER OF ELEMENTS FOR

UNDERFLOOR HEATING

WHY US?

SGI PRODUCT OFFER

FREQUENTLY ASKED QUESTIONS (FAQ)

Underfloor heating is a long-term investment for any property, and it’s crucial to seek advice from an underfloor heating specialist when selecting the best heating system. Depending on whether the property is newly built or already exists, different options for an appropriate system exist.

For newly built properties, wet underfloor heating systems are typically used due to greater technical capabilities. On the other hand, in already constructed buildings, it’s necessary to adapt to the existing infrastructure, such as the type of flooring, floor screed, ceilings, windows, and doors. Therefore, dry underfloor heating systems, including aluminum radiator-based aluplates or gypsum boards for drywall, may be more suitable.

It’s essential to note that different manufacturers offer various underfloor heating systems, and not all of them have both wet and dry systems available. Therefore, it’s necessary to choose a manufacturer that offers the desired heating system based on the specific needs and requirements of the property.

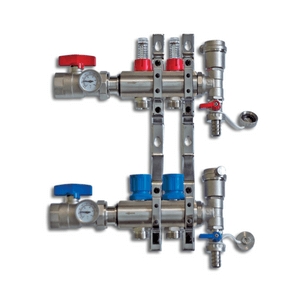

Integrating underfloor heating with a conventional radiator heating system is a viable option, but it involves lowering the temperature of the heating medium for the underfloor system. To achieve this, distribution manifolds with pumps specifically designed for underfloor heating are utilized, suitable for both wet and drywall systems. These manifolds ensure an efficient and even distribution of heat throughout the underfloor heating system, resulting in a more comfortable and energy-efficient living space.

Are you thinking of installing underfloor heating yourself? Before you begin, make sure you have the right equipment and preparation in place. Calculating the appropriate amounts and lengths of heating loops is crucial, and the type of underfloor heating system you choose will determine the tools you need.

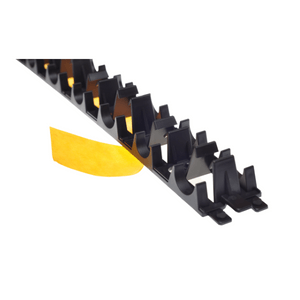

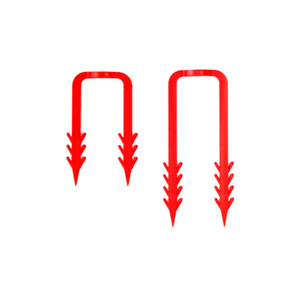

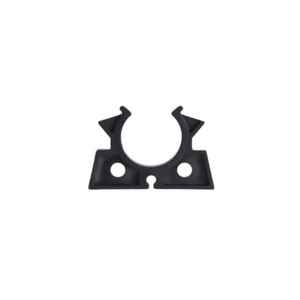

If you opt for the popular rail-type underfloor heating system, you won’t require specialized tools. The rail-type mounting strip comes in three varieties: adhesive, hooks, and holes. The adhesive strip has tape already attached to the rail, making it easy to attach to the substrate. The hooks strip can be fastened to a styrofoam substrate using hooks spaced every 20 cm on the rail. The holes strip can be attached to the substrate using screws, nails, or finger clips.

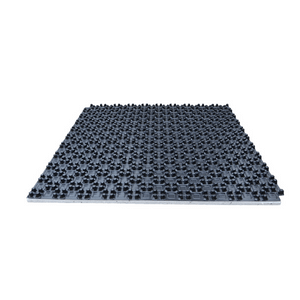

If you go for the tacker system, specialized tools such as a tacker, a device for inserting clips into underfloor heating, will be necessary. Other universal tools, like a pipe unwinder or pipe straightener, can speed up the installation process.

For dry underfloor heating systems, basic tools such as hammers and saws are required, and an arm-operated unwinder can make laying the pipe more efficient. With the right equipment and preparation, installing underfloor heating can be a straightforward DIY project.

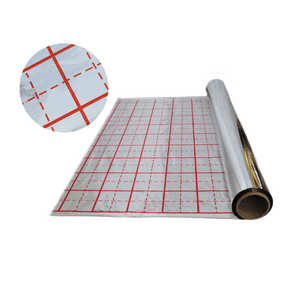

Looking to install water-based underfloor heating in your home or building? It’s important to know that this type of system is installed before a cement or anhydrite screed known as the underfloor heating screed.

The tacker system is the most popular wet underfloor heating system, using clips to attach the underfloor heating pipe to the insulation board with an underfloor heating clip gun, also known as a tacker for underfloor heating or a tacker for floor heating. These clips make installation easy and efficient, creating a complete heating system.

Once the underfloor heating system is installed, it’s covered with a wet or dry screed to create a heating plate. To reduce thermal expansion, an edge tape or insulation tape for underfloor heating should be embedded before the screed. An edge tape with a collar is required for anhydrite screed to prepare a tight tub for pouring.

Wet underfloor heating provides excellent efficiency and even distribution of temperature, making it a popular choice for new builds. However, in renovations or refurbishments where the thickness of the screed must be considered, dry installation systems are often preferred.

Dry underfloor heating systems without screed are becoming increasingly popular due to their many advantages, including quick and easy installation, reduced floor height, and low maintenance requirements. There are several types of dry underfloor heating systems available on the market.

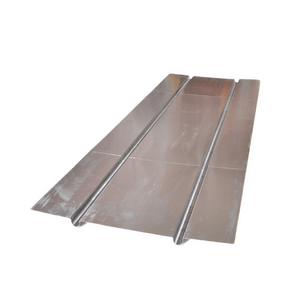

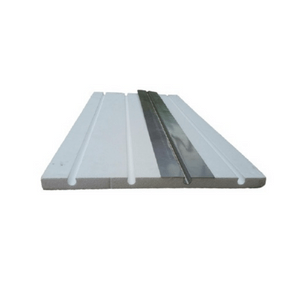

The most popular dry underfloor heating system is based on special aluminum plates called aluplates or aluplate, which are designed with an omega technology that encloses the underfloor heating pipe. These plates are placed on prepared polystyrene or chipboard plates, and a 18mm thick plasterboard fiber is then installed on top of the system. The resulting surface can be tiled or panelled directly, making it ideal for underfloor heating.

Another system for dry underfloor heating is the use of a special gypsum board with pre-grooved channels for laying the heating pipe. These systems require the use of a thinner 10 or 12 mm underfloor heating pipe. After laying the dry underfloor heating system, the gypsum boards can be covered with a gypsum fiber board or tiles can be laid directly on the board.

Chipboard plates are another system of dry underfloor heating that feature special grooves for laying the heating pipe. A variety of flooring materials such as gypsum fiber board, chipboard, floor panels, tiles, carpet, or carpeting can be laid on top of the chipboard plate for underfloor heating. These dry underfloor heating systems provide an efficient and cost-effective solution for heating homes and commercial buildings.

Radiant heat is the preferred method for underfloor heating as it emits most of the heat through radiation rather than convection. Underfloor heating is designed to have a lower temperature but covers a larger surface area to provide better heat distribution.

A well-installed underfloor heating system should have a temperature below 35 degrees Celsius. The radiant heat from underfloor heating can warm spaces up to 2 meters high, making it ideal for large areas like car showrooms or churches.

Underfloor heating is not supposed to cause convection or warm air rising to the top of a room. This is a myth. The temperature difference between the warm floor and the air does not cause convection, unlike traditional radiator heating. Radiant heat provides thermal comfort, giving us a feeling of warmth up to head height without overheating the upper parts of a room.

Underfloor heating is ideal for allergy sufferers and offers a healthy and cost-effective way to heat our homes. To illustrate its functionality, it’s like standing in front of a fire on a cold day, feeling warmth in front and coldness behind. Underfloor heating uses the same effect, where heat from the floor creates a comfortable and even warmth throughout the room.

Underfloor heating is known to be more cost-effective than traditional radiator heating due to its lower operating temperatures, resulting in reduced energy consumption. However, the efficiency of the underfloor heating system largely depends on proper planning and installation.

It’s recommended to consult an underfloor heating specialist during the design phase to ensure the system’s optimal performance. The specialist can assist in determining the most efficient layout and selecting the appropriate materials for installation.

By choosing the right components and having a well-designed layout, underfloor heating can provide long-term savings on heating costs, as well as improved comfort and better indoor air quality, especially for allergy sufferers. Don’t hesitate to contact an underfloor heating professional to get the most out of your system.

Floor heating control systems have come a long way and now offer advanced features for convenient and efficient heating control. With the widespread availability of smartphone apps and smart home systems, floor heating can be controlled remotely using WiFi connectivity.

However, it’s important to note that a well-installed floor heating system should not require constant adjustment or maintenance. The latest floor heating control systems are designed to be easy to use and require minimal intervention.

If you’re considering installing a floor heating system, it’s recommended to consult with a specialist who can provide guidance on the best control system for your specific needs. A properly installed and maintained system can provide efficient heating and comfort for many years to come.